Introduction: The Foundation and Challenges of the Automotive Industry

Automotive fasteners are critical components for vehicle structural integrity and safety. For procurement and technical engineers in the automotive industry, understanding their Key Manufacturing Processes is essential for cost control and ensuring compliance with stringent standards like IATF 16949. This article provides a professional, technical analysis of the core manufacturing stages, from raw materials to finished products, including the application of Artificial Intelligence (AI) in quality management.

A. Core Forming Technology: Cold Forging and Cold Extrusion

Cold Forging and Cold Extrusion are the primary forming technologies for high-strength, high-precision automotive fasteners. These techniques involve applying immense pressure to metal wire at room temperature, causing plastic deformation within a die. This process offers significant material savings (often >90% utilization) and produces superior mechanical properties due to the work-hardening effect, resulting in high precision and consistency suitable for mass production. Cold forging is ideal for complex external shapes (e.g., bolt heads, flanges), while cold extrusion is used for parts with large aspect ratios or complex internal shapes (e.g., bolt shanks, sleeves). The technical success hinges on precise die design and effective lubrication to protect the tooling and ensure smooth material flow.

| Technical Feature | Cold Forging | Cold Extrusion |

| Key Advantages | Material Savings, Superior Mechanical Properties, High Precision. | Suitable for large aspect ratio, hollow, or complex internal shapes. |

| Technical Focus | Die design, stress distribution, and die life. | Lubrication for smooth material flow and die protection. |

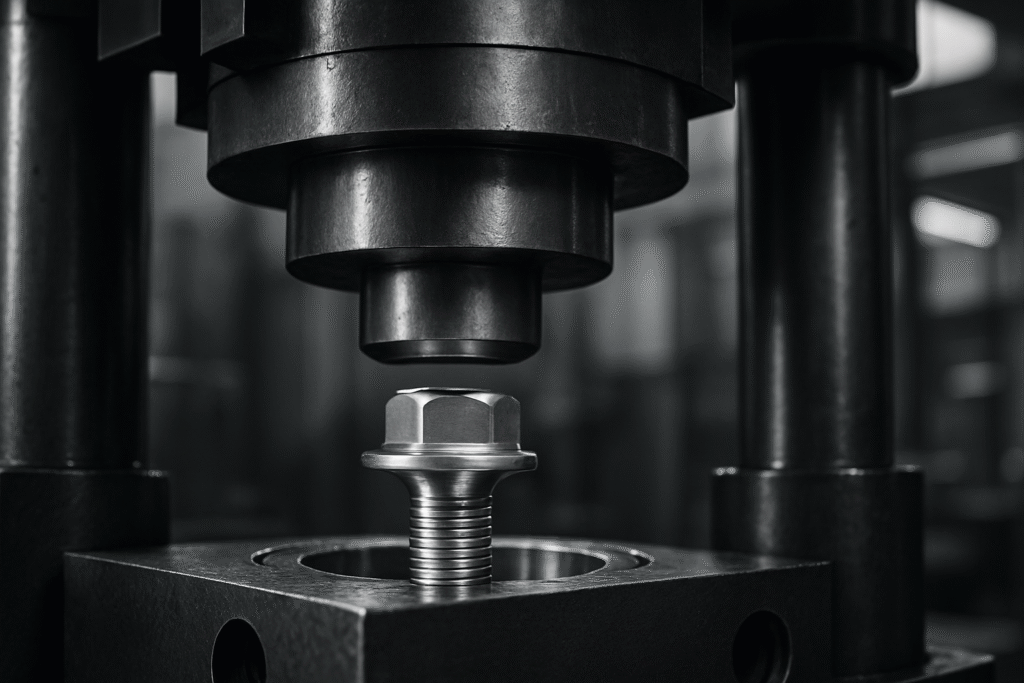

Figure 1: Precision Operation of a Multi-Station Cold Forging Machine

Professional cold forging equipment completes multiple processes on a single machine, enhancing efficiency and precision, and is the cornerstone for mass production of automotive fasteners.

B. Precision Machining and Secondary Forming: The Application of CNC

While cold forging handles most forming, CNC Precision Machining is vital for fasteners requiring extremely high precision, complex features, or specific thread processing. For high-strength fasteners, Thread Rolling is preferred over cutting. This plastic deformation process preserves the material’s grain flow, significantly boosting thread strength, fatigue resistance, and surface finish. CNC turning and milling are utilized for complex features like specialized chamfers, grooves, or irregular structures that cold forging cannot achieve, ensuring precise fit with automotive assemblies.

C. The Core of Performance: Heat Treatment Processes

Heat treatment is the critical step that determines a fastener’s Mechanical Properties—strength, hardness, toughness, and fatigue resistance. Precise control is paramount for Safety-Critical Fasteners. The main types include Quenching (to achieve high-hardness martensitic structure, controlled by temperature and cooling medium), Tempering (to reduce brittleness and adjust to the required strength level), and Carburizing (to increase surface hardness while maintaining core toughness). Modern continuous heat treatment furnaces ensure uniform heating and cooling under a controlled atmosphere, achieving the high batch-to-batch consistency demanded by the automotive industry.

| Heat Treatment Type | Purpose | Key Control Parameters |

| Quenching | Increase strength and hardness. | Temperature, soaking time, cooling medium. |

| Tempering | Reduce brittleness, adjust strength/toughness. | Temperature and time. |

| Carburizing | Increase surface hardness and wear resistance. | Carburizing depth and carbon potential. |

Figure 2: Continuous Mesh Belt Heat Treatment Furnace

Continuous heat treatment ensures uniform heating and cooling under a controlled atmosphere, guaranteeing high performance consistency for automotive components.

D. Corrosion Resistance and Functionality: Surface Treatment Technology

Fastener lifespan and reliability depend heavily on Corrosion Resistance, especially in the complex automotive environment. Electroplated Zinc and Zinc-Nickel Alloy are common treatments. Zinc-Nickel Plating is the preferred choice for high-end applications due to its superior corrosion resistance (>1000 hours salt spray) and low sensitivity to hydrogen embrittlement. A specialized challenge is Blind Hole Plating, where achieving uniform coating in deep holes requires precise control of the plating solution and current density. Subsequent De-embrittlement is mandatory to eliminate the risk of hydrogen embrittlement, ensuring long-term structural integrity.

E. Smart Manufacturing and Quality Assurance: AI in Quality Control

The automotive industry’s zero-defect goal necessitates moving beyond traditional manual inspection. Artificial Intelligence (AI) is revolutionizing quality control by enabling more efficient and reliable inspection. Key applications include: Automated Optical Inspection (AOI), where AI-driven systems perform 100% full inspection of geometry and surface defects (cracks, burrs) with high speed and accuracy; Predictive Maintenance, where AI models monitor equipment data (e.g., cold forging machines, heat treatment furnaces) to predict failures and ensure production continuity; and Material Composition Analysis, where AI-assisted spectrographic analysis instantly verifies material compliance. This integration of AI minimizes human error and is crucial for achieving automotive-grade quality.

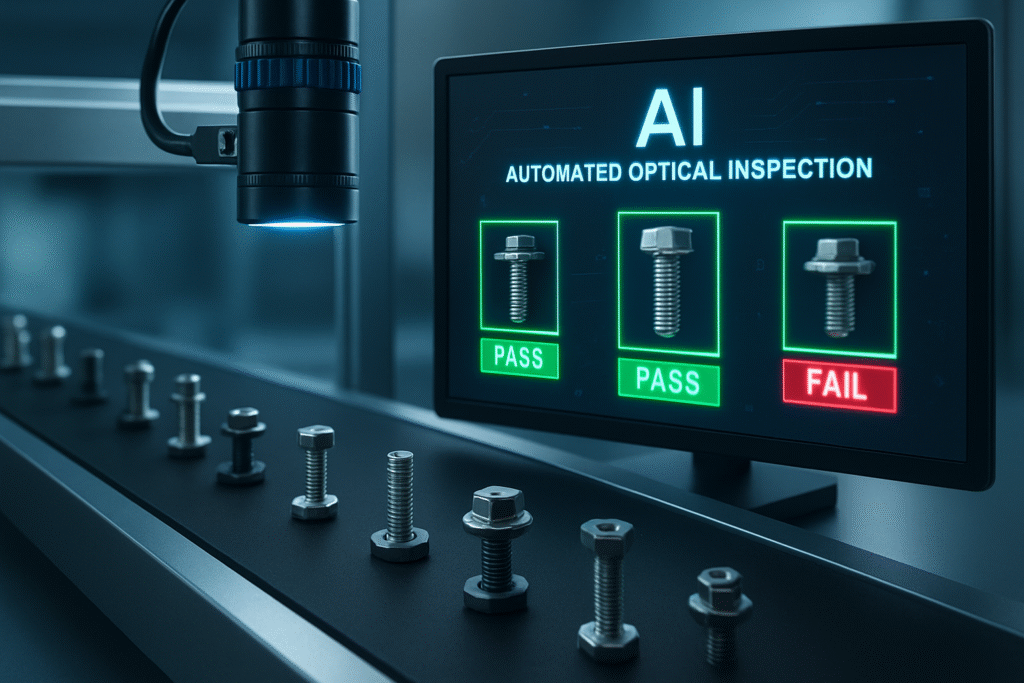

Figure 3: AI Automated Optical Inspection System

Utilizing high-resolution cameras and deep learning, the AI system instantly identifies and classifies minute defects, minimizing human error and serving as a key technology for achieving zero-defect goals.

Conclusion: Technical Depth and Supply Chain Reliability

For automotive procurement and technical engineers, selecting a fastener supplier is an evaluation of their Manufacturing Technical Depth, Quality Control System, and Supply Chain Resilience. A reliable partner must demonstrate expertise in advanced cold forging, precise heat treatment, specialized anti-corrosion technology, and an active adoption of AI smart quality control. These capabilities are non-negotiable for safeguarding the safety and performance of automotive products.

Technical Q&A: Automotive Fastener Excellence

(Click the triangle to see the answer.)

1. Why are automotive fasteners mostly produced via cold forging?

Cold forging is preferred because it maintains the metal’s “Grain Flow” without cutting the internal fibers. This strengthens the part’s resistance to fatigue and stress, which is vital for safety-critical automotive applications compared to traditional machining.

2. How does IATF 16949 certification impact the manufacturing process?

The IATF 16949 standard mandates strict controls over raw material traceability and process stability. It requires proactive risk management (FMEA) to ensure world-class consistency and a “Zero Defect” manufacturing target.

3. What new requirements does the rise of EVs bring to the industry?

Electric Vehicles demand lightweighting (using aluminum or hollow designs) and specific electrical properties. This requires advanced machining centers to handle specialized materials and tighter tolerances for battery and motor assemblies.

4. How do you prevent fasteners from loosening under long-term vibration?

We combine high-precision thread rolling with secondary treatments such as pre-applied adhesives (e.g., Nylok). These treatments increase the frictional break-away torque, ensuring safety for chassis and powertrain components.

5. How does Excel Components handle complex blind hole automotive parts?

Leveraging nearly 50 years of expertise, we use vacuum-assisted plating and specialized tool paths to ensure deep blind holes achieve perfect dimensions and 1000+ hours of salt spray corrosion resistance.

Your Trusted Automotive Supply Chain Partner

Partner with Excel Components to leverage nearly five decades of precision engineering and IATF 16949 certified manufacturing for your next automotive project.

Request a Technical Consultation