Excel Components MFG – Overcoming the Hidden Challenge

The 4 Technical Bottlenecks of Blind Hole Plating

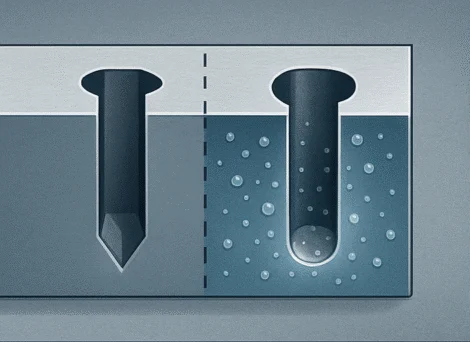

- Air Trapping: Air bubbles get trapped at the bottom, creating a physical barrier that prevents plating.

- Ion Depletion: High aspect ratios prevent fresh chemical ions from reaching the deep corners of the hole.

- Uneven Current Distribution: The “dog-bone effect” causes thick plating at the rim and almost none at the base.

- Chemical Residues: Trapped acids can corrode the part from the inside out weeks after production.

Excel Components’ Systematic Solutions

- Prevention at the Design Stage (DFM)

Over 80% of manufacturing issues originate in design. By optimizing the aspect ratio, adding internal fillets, and clearly defining plating requirements, we can eliminate problems at the most cost-effective stage.

- Thorough Pre-treatment & Cleaning

Blind holes are traps for contaminants. Ultrasonic degreasing and multi-stage rinsing are critical to ensure the internal surfaces are pristine, providing a perfect foundation for strong plating adhesion.

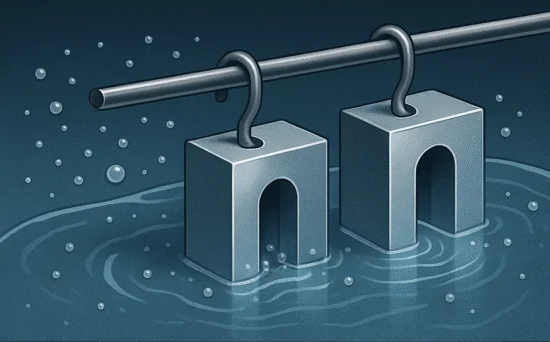

- Precision Control During Plating

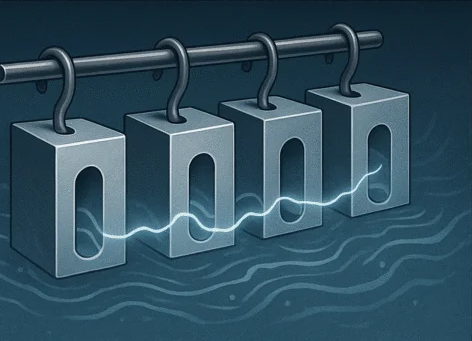

This is the core of the solution. Through expert jigging, enhanced solution agitation (e.g., pulse plating), and selecting a process with high throwing power like Electroless Nickel (ENP), we overcome the physical barriers.

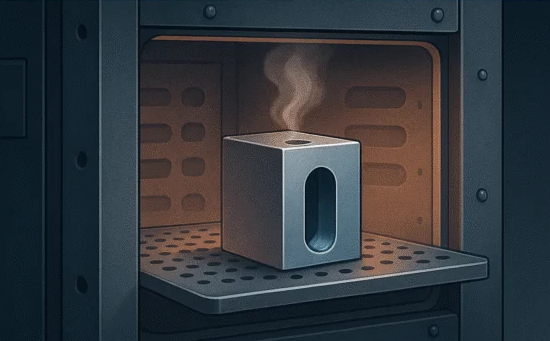

- Meticulous Post-Treatment & Drying

To prevent future “acid bleed-out,” parts undergo neutralization, hot water rinses, and thorough oven baking to ensure no residual chemicals or moisture remain trapped inside the blind hole, guaranteeing long-term reliability.

To ensure perfect protection even in the deepest holes, we implement a multi-dimensional approach:

- Vacuum & Ultrasonic Pre-treatment: Forced air removal ensures 100% liquid saturation in micro-spaces.

- Pulse Plating Technology: High-frequency current cycles allow ions to redistribute, significantly improving “throwing power.”

- Physical Vibration & Rotation: Automated lines use vibration to solve ion starvation in high-aspect-ratio parts.

- IATF 16949 Standards: Verified quality through Cross-section Analysis and metallurgical microscopy.

Blind Hole Plating: Technical Q&A

(Click the triangle to check our answer.)

1. What type of blind holes are most difficult to plate?

2. How to verify success at the bottom of the hole?

3. Can pressure solve the air bubble issue?

4. What happens if blind hole plating fails?

5. Can you handle micro blind holes (< 1mm)?

Solve Your Plating Challenges Today

Leverage our 50-year engineering legacy and IATF 16949 certified systems for your most complex parts.