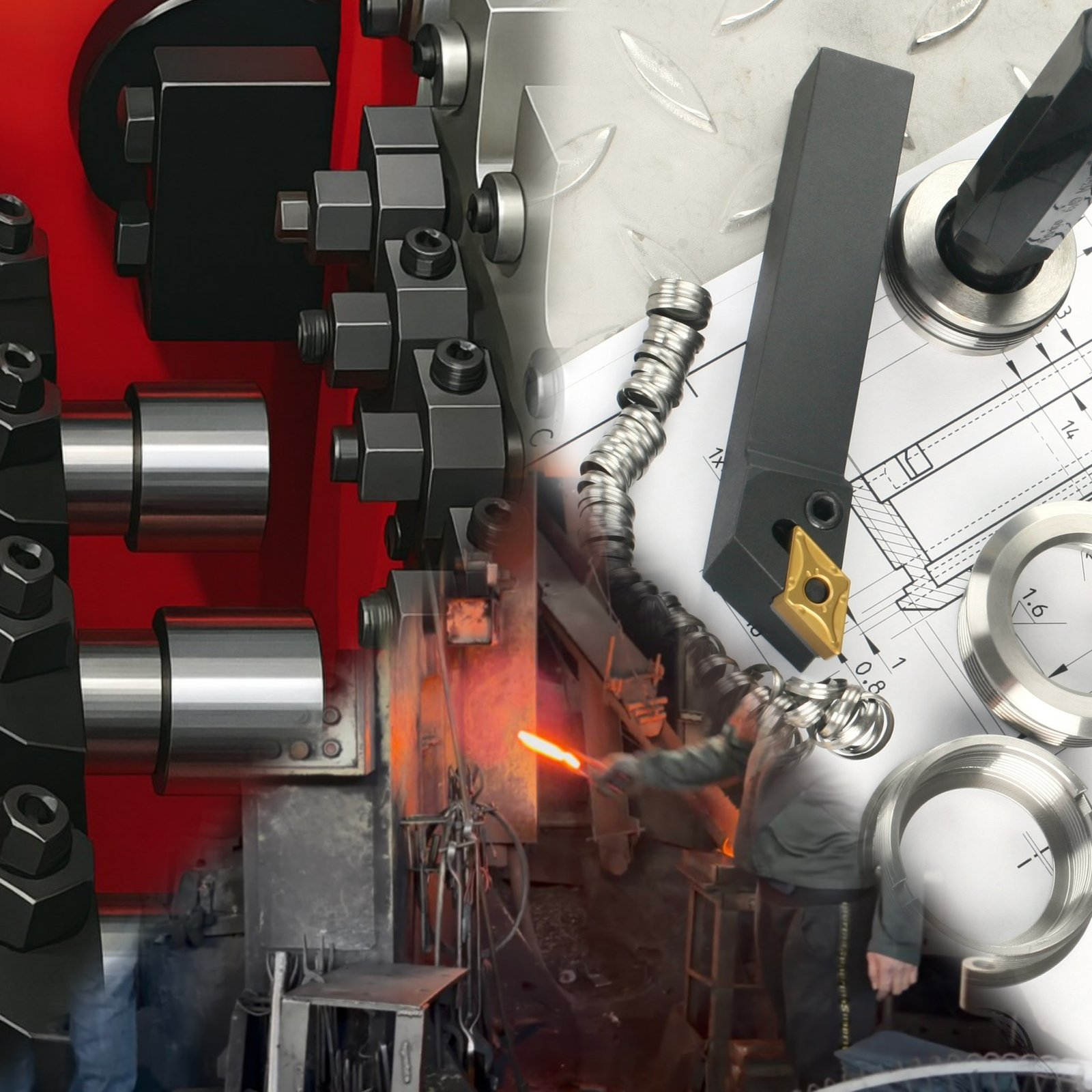

We take great pride in our stable and high-quality machinery. From precision lathes and milling machines to advanced machining centers, we meticulously control the selection, calibration, and maintenance of every piece of equipment. This ensures exceptionally high stability and precision during operation, with achievable tolerances as tight as +/-0.005mm and +/-0.01mm. This is not only reflected in the high performance of the machinery itself but also in our stringent management of production processes. Stable equipment serves as a strong guarantee for us to meet customers’ rigorous requirements for part accuracy, surface finish, and dimensional tolerances, and it is also the key to our ability to undertake complex precision parts manufacturing.

Diameter: 0.50 - 250 mm; Length: 1.50 – 800 mm

800L x 450W x 500H mm

| Material | Specifications |

|---|---|

| Carbon Steel | 1215 • 1215MS • 12L14 • 1144 • C1008 • C1010 • C1015 • C1018 • C1020 • C1022 • C1035 • C1040 • C1045 • C1050 • GB#10 • GB#15 • GB#18 • A • GB#20 • GB#35 • GB#45 • SS400 • Q215 • Q235 • A3 • SPCC • S15C • S20C • S45C • SAE 1020… |

| Alloy Steel | 42CrMo • 42CrMo4 • 42CrMoS4 • 35CrMo • 20CrMo • 40Cr • 20Cr • 4140 • SCM435 • SCM440 • SCM415 • SCM420 • SNCM220 • 35ACR • Q345 • 65Mn • GCr15 • 52100 |

| Stainless Steel | 301 • 302 • 303 • 303Cu • 304 • 304L • 316 • 316L • 316F • 430 • 430F • 416 • SUS420J2 • SUS630 |

| Aluminum Alloys | 2011 • 2024 • 6082 • 6060 • 6061 • 6063 • 6082 • 7075… |

| Copper / Bronze | T2 (C1100), C11000 • C65100 • C91700… |

| Brass | C3604 • C36000 • C3771 • C2600 • C2700 • C2680 • C2801 • H59 • H62 • H65 • HPb59-1 • HPb63-3 • 26000 • 27000… |

| Cast Iron | HT250… |

| ITEM | BRAND | MODEL | QTY |

| Multi-Axis Fixed-Head Lathe | JINGFUSI | CK46-4+4+Y | 2 |

| HONG QUAN | LT-30M | 5 | |

| HONG QUAN | LT-36M | 2 | |

| HONG QUAN | LT-46M | 1 | |

| Multi-Axis Swiss-Type Lathe | CITIZEN | L20 | 1 |

| STAR | SB-16 | 4 | |

| CITIZEN | B20 | 7 | |

| STAR | SB-20J | 1 | |

| STAR | SB-20RG | 2 | |

| STAR | SP-23 | 4 | |

| STAR | SR-32JM | 3 | |

| 4-Axis Machine Center | NEWAY | VM-1050S | 3 |

| Multi-Axis Swiss-Type Lathe | STAR | SR-10J | 3 |

| STAR | SB-16 | 2 | |

| STAR | SB-16D | 3 | |

| STAR | SE-16 | 1 | |

| STAR | SB-20RG | 1 | |

| STAR | SB-20R2 | 1 | |

| Multi-Axis Fixed-Head Lathe | STAR | SR-32JC | 2 |

| Cold Forging Machine | 6 Die 6 Blow | Wire Dia. ø12mm max. Forging Dia. ø20 mm max. | Wire L: 150mm max. Forging L: 120 mm max |

| 6 Die 6 Blow | Wire Dia. ø19mm max. Forging Dia. ø40 mm max | Wire L: 330mm max. Forging L: 200 mm max. | |

7 Die 7 Blow Extended type | Wire Dia. ø14mm max. Forging Dia. ø14 mm max. Hex.: 11mm max. | Wire L: 70mm max. Forging L: 50 mm max. | |

6 Die 6 Blow Extended type | Wire Dia. ø15mm max. Forging Dia. ø18mm max. Hex.: 14mm max. | Wire L: 85mm max. Forging L: 78 mm max. | |

| Pneumatic Punch Press | 2 | ||

| CNC Lathe | 2 | ||

| Desktop Lathe 15# | 1 | ||

| Desktop Lathe 20# | 1 | ||

| Thread Rolling Machine | 1 | ||

| Drilling & Tapping Machine | 2 | ||

| Vibrating Machine | 2 | ||

| De-oiling Machine | 3 | ||

| Cutting Machine | 4 | ||

| Grinding Machine | 3 | ||

| Air Storage Tank | 2 | ||

| 3D Vibratory Cleaning Machine | 2 | ||

| Magnetic Grinding Machine | 2 | ||

| Ultrasonic Cleaning Machine | 2 | ||

| Electric Constant-Temperature Hot Air Drying Oven | 2 | ||

In high-intensity, fast-paced production environments, to mitigate the risks of human error, we have established a rigorous “Color Management System.” This system utilizes intuitive color coding to precisely distinguish product statuses such as “Ready for Shipment,” “Pending Inspection,” and “Rejected for Shipment.” This system not only significantly reduces the risk of inadvertently mixing pending inspection or non-conforming products into outgoing shipments but also fundamentally guarantees shipping accuracy, ensuring that every product reaching our customers meets the highest quality standards from the source.

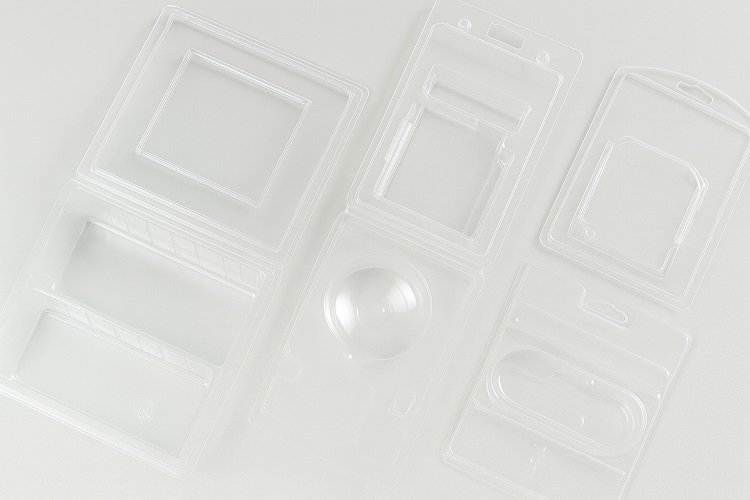

We offer a diverse range of customization options, including material selection (such as plastic bags, paper boxes, blister packs, metal cans, cushioning materials), size specifications (customized according to product characteristics), label design (brand, product name, barcodes, etc.), structural design (e.g., vacuum forming, multi-layer composites, separate compartments), and printing and special treatments (such as anti-static, scratch-resistant, anti-rust, high barrier properties, etc.) to meet the storage, display, and transportation needs of various hardware products.

Address : No.116, Wanxing St., Sanmin Dist., Kaohsiung City 807, Taiwan

TEL : +886 7 3909222

FAX : +886 7 3802921

E-mail : market@excelcomponents.com.tw

Address : 1&2 Floor, Building 32, Liandong U Valley Yinzhou Intelligent Manufacturing Industrial Park, Heyicun, Jiangshan Town, Yinzhou District, Ningbo, Zhejiang Province, 315195, China